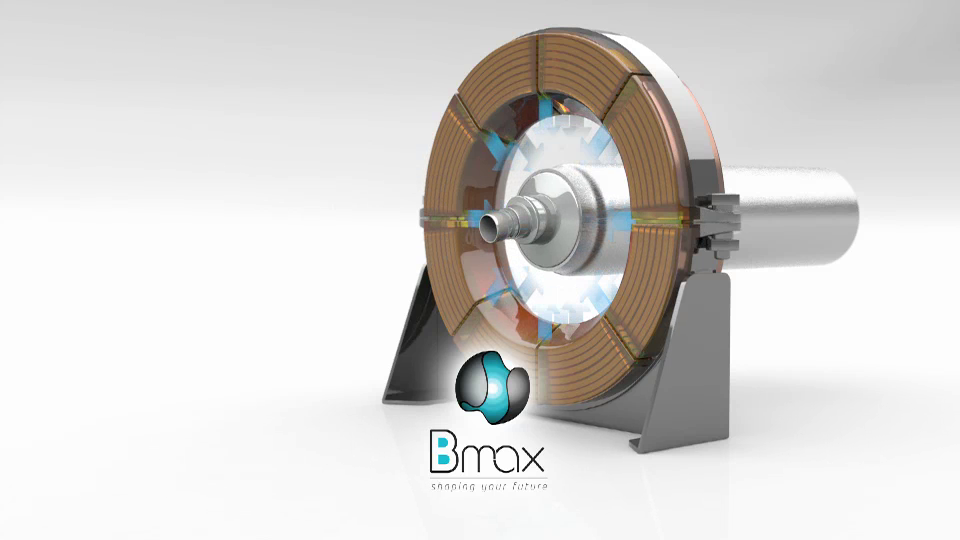

About Bmax

Our industrial solutions based on using High Pulsed Power (HPP) are a unique, efficient, and clean alternative capable of revolutionizing the world of metal joining and shaping. They also provide new opportunities in product design and material selection.

Bmax, a subsidiary of I-Pulse and a global leader in utilizing High Pulsed Power (HPP) technology, operates manufacturing facilities in both France and the United States. Our expert teams develop all products, systems, and related services at these locations. Bmax is well-equipped to meet the needs of diverse markets, including e-Mobility, aerospace, and luxury packaging.

Contact us

Would you like more information about our systems and products? Contact our sales team to learn about our breakthrough technology.

Our solutions tailored for your market

We can guide you to find the most effective solution.

You are

E-Mobility

The growing hybridization & electrification of vehicles is generating new needs that conventional joining technologies can no longer satisfy.

Aerospace

The Aerospace industry needs to accelerate its race for technological innovation by implementing new, efficient production processes.

Luxury

Providing responsible, sustainable product packaging has become a major challenge and a key commitment for many companies.

Latest

news

Bmax & You

Joining Bmax means being part of a team with over ten years’ experience in the pulsed power field and bringing your expertise to high tech projects that break with traditional production methods and processes.

apply to

Our Job Offers

Joining Bmax means becoming a valued member of a team where everyone is empowered to maximize their know-how, grow their skills and work collaboratively to best satisfy our customers’ needs while complying with quality and safety standards.